Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Schleich MotorAnalyzer3

The expert level tester for your motor service

New Paragraph

New Title

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Motor Analyzer 3 Details:

The universal tool.

The MotorAnalyzer3 is the mobile ALL-IN-ONE test device for electric motor service and repair, electric motor repair, and maintenance and service.

The combination of precise measurement technology, forward-looking software, intuitive operation, and 17 integrated test methods makes the MotorAnalyzer3 the most powerful mobileelectric motor test devicefor electric motor service and repair. The device a unique integrated test method switch, which automatically switches all available test methods to the winding terminals. Simplyconnectthe device to perform all tests automatically.

Unrivalled versatility. A class of its own.

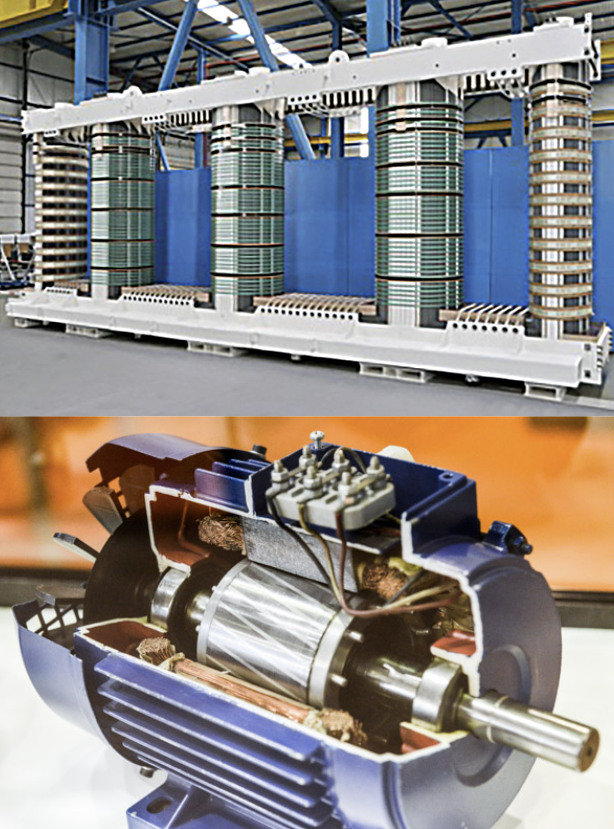

Universal ALL-IN-ONE testing device for:

3-phase motors and generators

Asynchronous motors, induction motors

AC and DC generators

AC and DC synchronous motors

servos

DC motors

Brushless DC

Wound armature fields

Electric motor brake coils, clutch coils

Single-phase electric motors

1-, 3-phase transformers

…

17 Test methods

Complete electric motor condition analysis in just a few minutes

Manual and automatic checks

Fully automatic test method switching on the 4 measuring lines

Testing can also be performed via long connecting cables to electric motor at the control cabinet.

Integrated voltage measurement function before the start of the test to protect the test device

Highly readable, large, high-resolution touch display

Integrated test result memory thousands of tests performed

Real-time clock for storing time and date

Input of electric motor nominal data, customer data, and location data for the perfect test protocol

PC software PrintCom for Save printing test results a PC

Transfer of test results to a PC test results Bluetooth

Software with integrated instructions and help texts

Free lifetime updates for your MotorAnalyzer3 via PrintCom and Internet connection

Makita® replacement batteries – high productivity thanks to cordless operation

Lightweight

Robust, impact-resistant outdoor carrying case with all measuring cables "on board"

Optimized for:

fault detection and localization

quality control

Input and output control of new, defective, andrepairedwindings

trend analysis

Preventive maintenance

Technical specifications overview

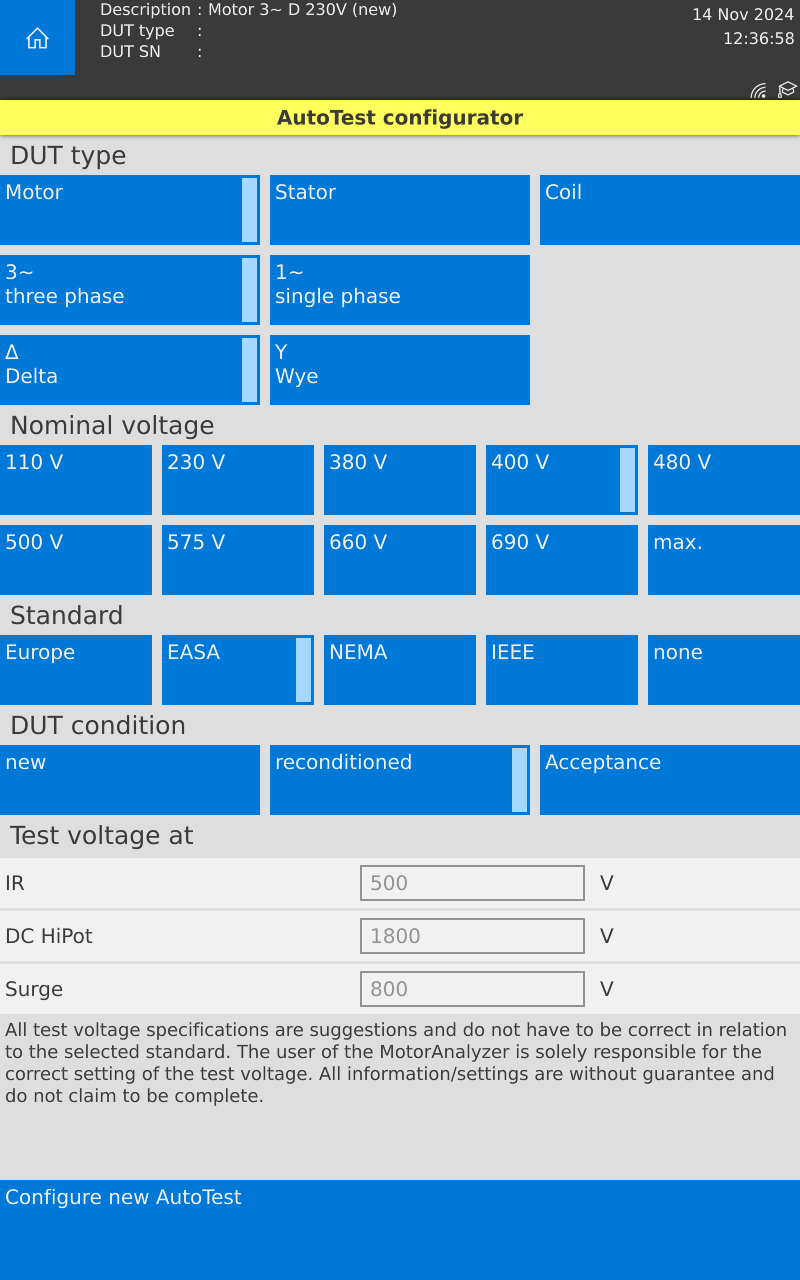

Autotest

automatic stator- and motor-tests

fully-automatic fault analysis

connect once – then test everything

automatic switching between the test methods

automatic switching between the up to 4 test leads

Surge voltage

up to 3,000 V

automatic and manual surge voltage tests

surge voltage tests specifically designed for stators

surge voltage tests specifically designed for fully assembled motors

automatic stepwise test voltage increase (peak to peak)

1, 2 and 3-phase

graphical visualization of the surge wave

automatic analysis

Resistance

1, 2 and 3-phase

imbalance analysis – scattering between phases

high-precision 4-wire measurement (4W)

ambient/winding temperature compensation

Inductance

1-, 2- and 3-phase

imbalance analysis – scattering between phases

high-precision 4-wire measurement

RIC-Test (Rotor Influence Check) – squirrel cage rotor test

3-phase

measurement of the angle-dependent asymmetry of the squirrel-cage rotor

Impedance

1-, 2- and 3-phase

imbalance analysis – scattering between phases

high-precision 4-wire measurement (4W)

High voltage DC

0 – 6,000 V DC

manually adjustable

programmable (automatic)

step voltage test

Polarization index & DAR

0 – 6,000 V DC

PI-test

DAR-test

automated measurement

Insulation resistance

0 – 6,000 V DC

up to 500 GΩ (1 TΩ)

e.g. with 500 V in accordance with VDE 0701

ambient/winding temperature compensation

PE/GB-resistance

in accordance with VDE 0701

Capacitance

Capacitance between the entire coils and the motor frame

Neutral Zone adjustment for DC motors

bar chart indicating the deviation from the neutral zone

acoustic indication of the misalignment from the neutral zone by means of a signal tone

This allows you to optimally concentrate on adjustment during the measurement – and you do not have to look at the display.

Rotary Field of the stator

stator – rotary field measurement with a rotary field probe

Sense of rotation of the motor

motor – sense of rotation measurement

Locating the slots with Turn-to-Turn fault

Locating the slot in which the turn-to-turn fault is located by means of a test probe

for stators and wound rotors

bar chart indicating the slot to slot deviation

modulated acoustic notification if test results are outside the specified limits

This allows you to optimally concentrate on the positioning of the measuring probe above the slot during the measurement – and you do not have to look at the display.

Power Supply

built-in rechargeable battery

wide range of line voltages: 90 – 250 V, 47 – 63 Hz

key switch for activation

This means that, if necessary, the MotorAnalyzer can only be used by authorized persons.